Journey from 1990 till date

2022

We have production capacity of 400 Tons, with printing capacity 450 Tons & almost 350 Tons bags & pouch making capacity.

2018

- We added new line with very high standard UTECO, Italy 8 colour C.I. machine with 1350 mm printing width & speed of 500 M.T/minute. Company had introduced “Crystal” model for the first time in India.

2016

Investment of Rs 240 Million in land property across 1,30,000 sq.ft in Vapi, Gujarat, construction of almost 80,000 sq.ft. with international standards was successfully executed.

2015

- USA company approached back with courier bag order basis to our past performance and we added assets worth 15 Million for new product development.

2011

Installed 3 Layer Blown Film plant of width upto 2 Mtrs

2010

- A US based manufacturer was contacted for Patch Handle bags with a

4 months deadline. We invested 20 Million in this equipment, and the USA Company's "Social Audit" of our sample was a complete success. The company placed an order for 180 Million, and it was completed promptly and to high standards of quality.

2009

The capacity of production has gone upto 200 Tons per month with almost 25 Million bags capacity per month.

2008

- Expanded the company in the name of Glassopack Pvt. Ltd. in multicolor printing. Imported modernise machinery in LDPE/ HM/PP with three-layer machine & printing new technology with 8 colour print from Taiwan was added to the asset.

2007

Additional Investment of 80 Million to purchase 4000 sq.mtr plot and construction area of almost 3000 sq.mtr.

2006

- We became India’s 1st manufactures to produce 0.8 Million bags with apt quality check.

2004

We added more machinery worth Rs 22.5 Million which manufactures Standy Bags, Wave top Bags and Polydraw Bags.

2002

- For the first time in India, we are the visionaries who introduced advanced loop handle machines for the manufacturing of carry bags and standy bags. Our cutting-edge technology ensures high precision, high accuracy, high quality, and excellence, setting a new benchmark in the industry.

2001

- we became the 1st Company to start with 100% automised loop handle carry bags with Investment of 6.7 Million.

1999

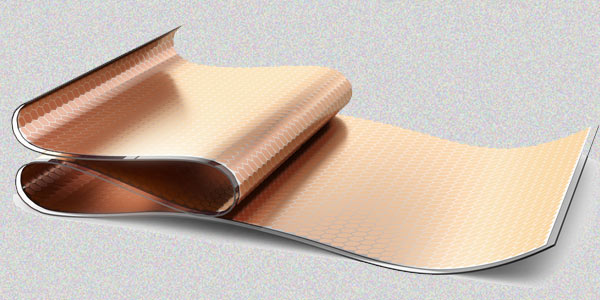

Started the manufacturing of multi-layer film

1998

- We added assets from Germany, machine used for two-layer manufacturing with best quality output.

1994

To meet the evolving market demands, we strategically invested in an advanced LDPE plain and printed extrusion and printing unit. This investment enables us to enhance production efficiency and cater to diverse customer requirements with high-quality output, ensuring our continued leadership in the industry.

We invested in cutting-edge LDPE plain and printed extrusion and printing technology to improve production efficiency, meet market demand, and offer premium, customized solutions, reinforcing our industry leadership.

1990

- LDPE plain & printed so we invested for ldpe extruion & printing unit